REGIONAL AND EUROPEAN PROJECTS

PARTNERSHIPS WITH UNIVERSITIES AND RESEARCH INSTITUTES

European Project REMODEL – Robotic tEchnologies for the Manipulation of cOmplex DeformablE Linear objects.

ENKI srl is very proud to announce its entering in the consortium of the REMODEL project.

It is a great opportunity to cooperate and share solutions with these expert partners following our path of continuous improving and innovation.

European Project ForZDM – Zero Defect Manufacturing

Project ID: 723698, Funded under: H2020-EU.2.1.5.1. – Technologies for Factories of the Future – Integrated Zero Defect Manufacturing Solution for High Value Adding Multi-stage Manufacturing systems

Innovative proactive Quality Control system for in-process multi-stage defect reduction

7° PQ – (Seventh Framework Programme ) European Project:

Towards zero-defect manufacturing – FP7-2011-NMP-ICT-FoF.NMP.2011-5

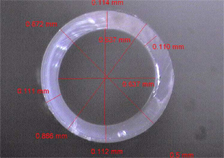

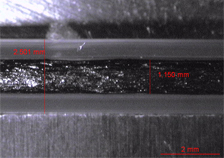

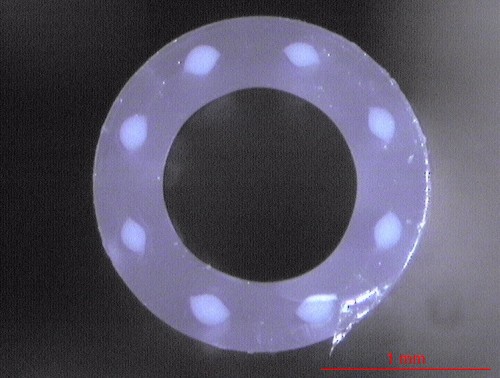

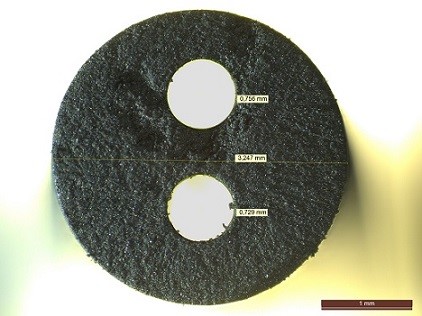

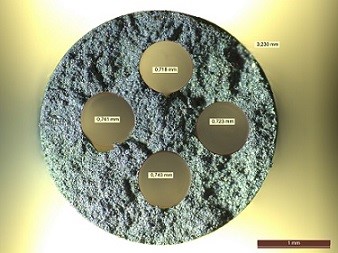

“New materials and extrusion techniques in the production of endovascular catheters” -ATP project

Project of the Lombardy Region – Line of intervention 1.1.1.1.A Tender Notice “ATP 2009 ”

“PEM for medical devices” – MIUR project

(Ministry of education, university, and research)

Project of the Lombardy Region – Line of action “tender notice to submit industrial research projects and experimental development in strategic sectors of the Lombardy Region and the MIUR” (Ministry of education, university, and research)” Managerial Decree Operation Unit 29 July 2011 n.7128