-

ENKI uses a wide range of materials. Our qualified staff offers customers the knowhow when choosing the material or the combination of materials that will give them the best performance for their final product.

-

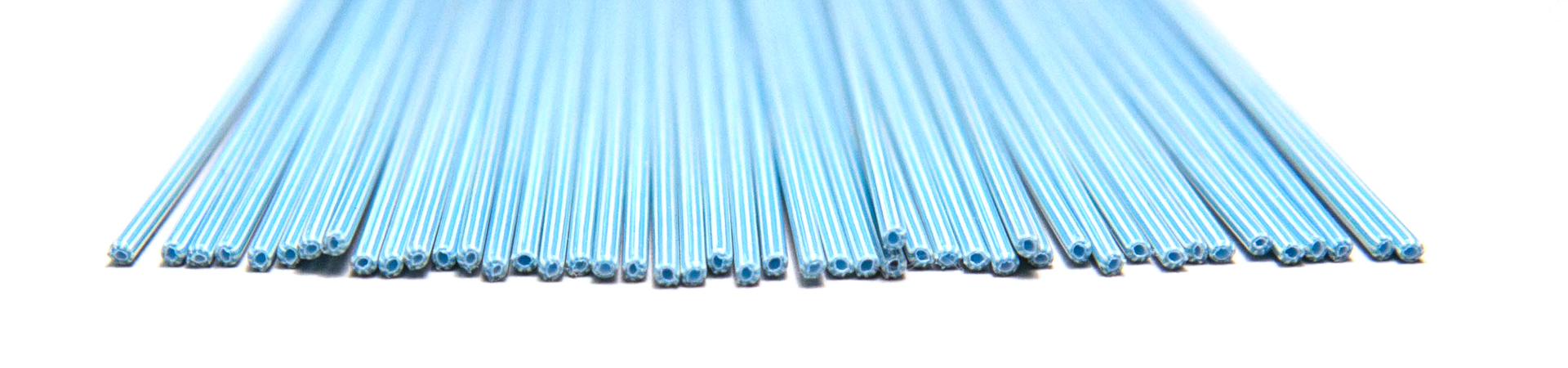

ENKI develops and manufactures special microtubes, wires and profiles used in the most different fields. Thanks to our experience we can provide tubing with very small diameters up to 0,10mm with tight tolerance up to +/-0,015 mm (15 μm) according to your request.

EXAMPLES OF TUBE SECTIONS

ENKI engineers and manufactures different types of multi-lumen, multi-layer, modular flexibility tubing and braided tubes.

![]()

EXAMPLES OF SPLITTABLE TUBING

THANKS TO OUR TECHNOLOGIES AND KNOWHOW, ON EXTRUDED PROFILES AND TUBES, WE ARE ABLE TO PERFORM THE FOLLOWING PROCESSES: